Special composition PVC

Besides the standard profiles made of PVC, DSU also offers profiles in a different material composition. Each material has specific properties with regard to temperature range, ease of installation and service life.

| |

Standard Profiles |

Soft Profiles |

Extended Life Profiles |

| Material |

PVC |

Soft PVC |

TPE |

| Profile code |

-M, -A (195-M) |

-MS, -AS (195-MS) |

-ME, -AE (195-ME) |

| Temperature range |

-5 °C to +40 °C |

-20 °C to +40 °C |

-40 °C to +130 °C |

| Installation |

|

|

|

| Life span |

|

|

|

Temperature range

The choice of material is partly determined by the temperature range of the application. The flexibility of a standard profile decreases rapidly as the temperature decreases. Profiles based on soft PVC or TPE are more flexible than standard PVC, even at low temperatures. The degree of flexibility of the material used also affects the service life. A brittle non-flexible seal is more likely to crack. In freezers, a heater tape is often installed so that the seal does not freeze and remains flexible and thus has a longer lifespan.

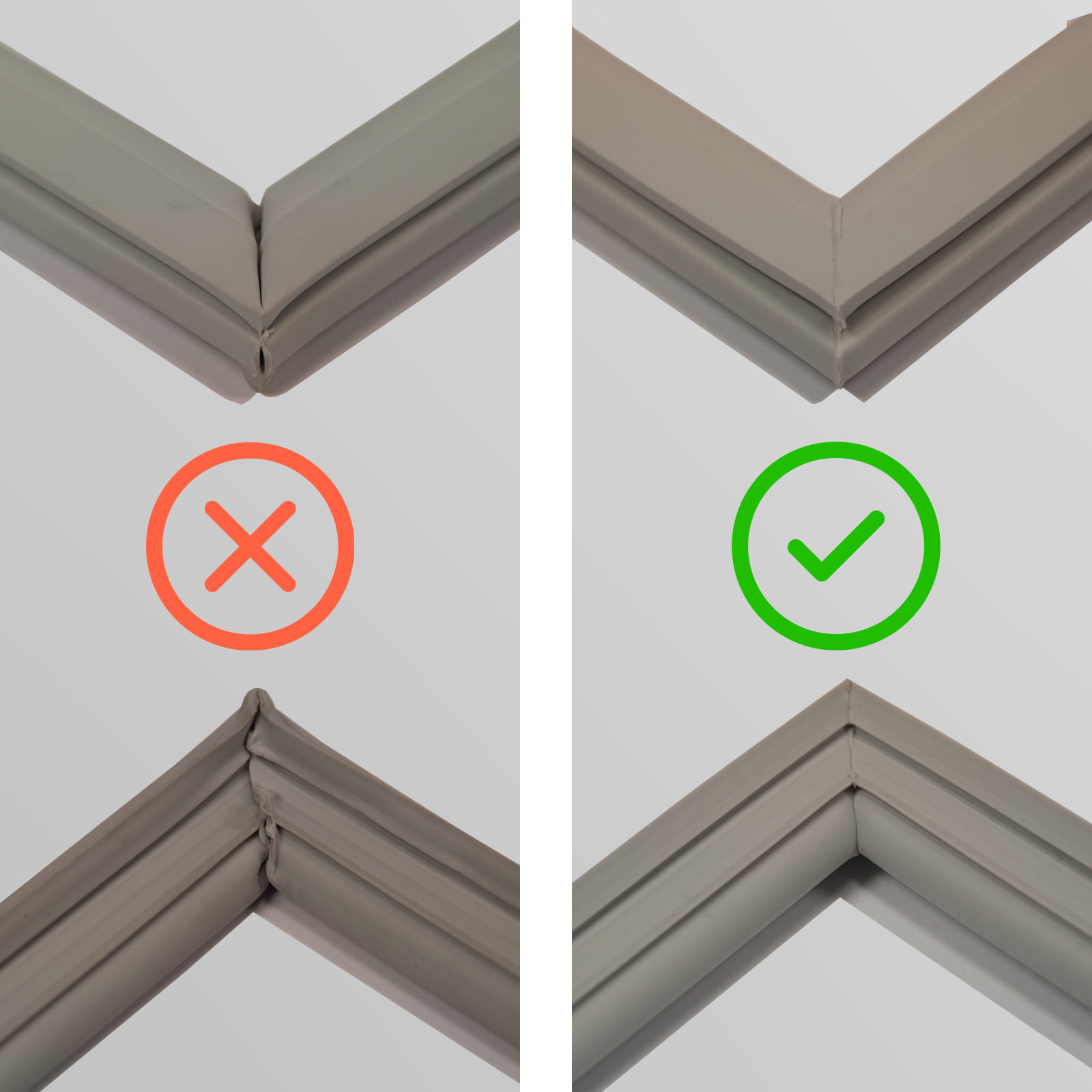

Installation

The degree of flexibility of the material is related to how easily and quickly seals can be installed on a door or drawer. When fitting seals made of PVC, it is often necessary to heat them to remove folds and creases caused by storage and transport.The highly flexible seals made of TPE deform to a lesser extent during transport and are quicker and easier to fit.

Life span

Maintaining seals is important from a hygiene point of view but certainly also for optimal life span. The effects of dirt, grease and/or (aggressive) cleaning agents cause seals made of PVC to dry out more quickly and, as a result, crack.

Thanks to the material properties of TPE, Extended Life profiles are less sensitive to the effect of dirt, grease and/or (aggressive) cleaning agents and therefore have a longer lifespan. Seals made of TPE are always the best choice for equipment with a high intensity of use as well as for (blast) freezers, heated cabinets and climate cabinets.